History of NASA Langley

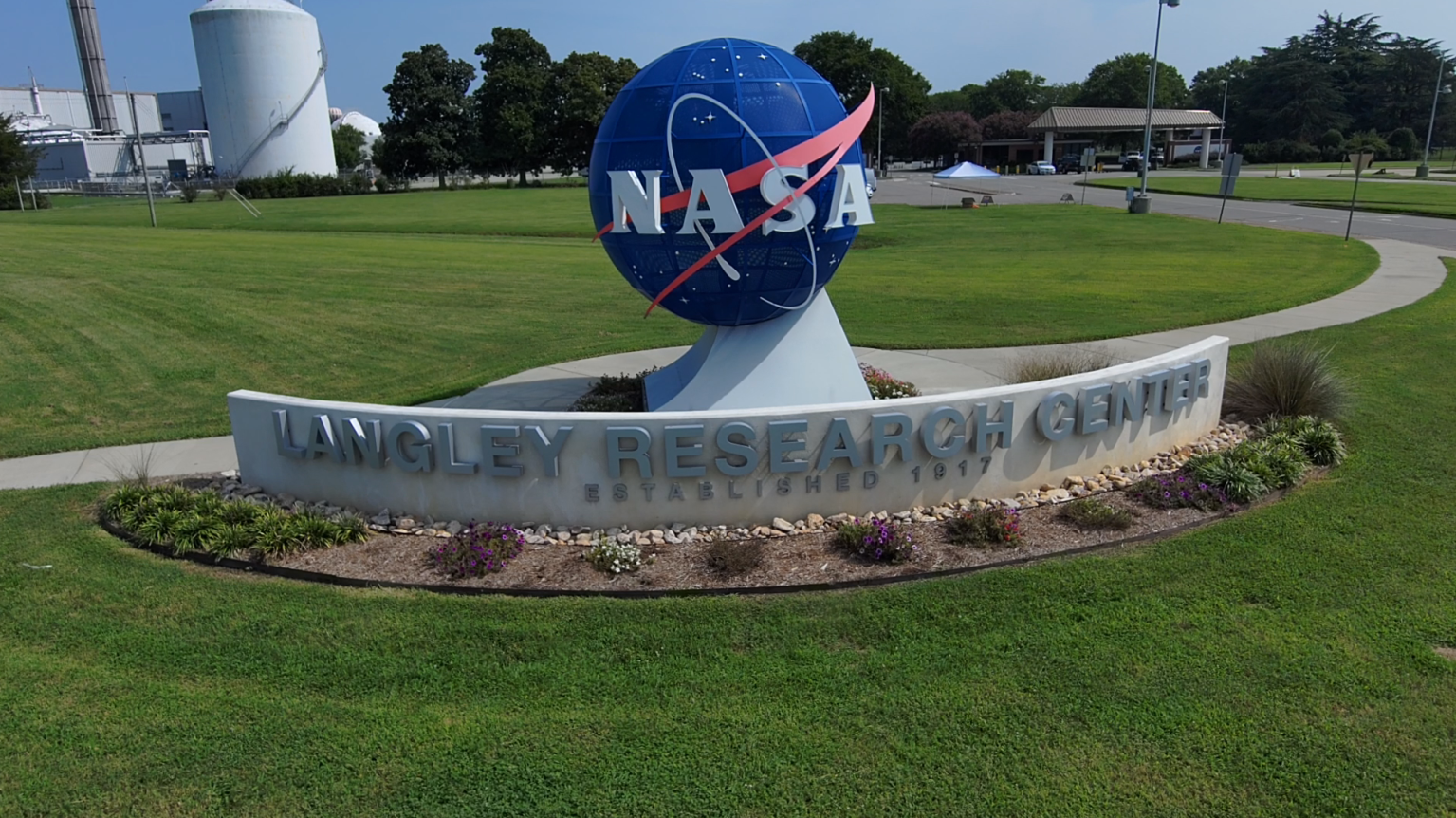

NASA Langley Research Center is a place where past discoveries meet future innovations. Welcome to NASA’s first field center.

OVER A CENTURY OF INNOVATION

years since Langley’s founding

facilities

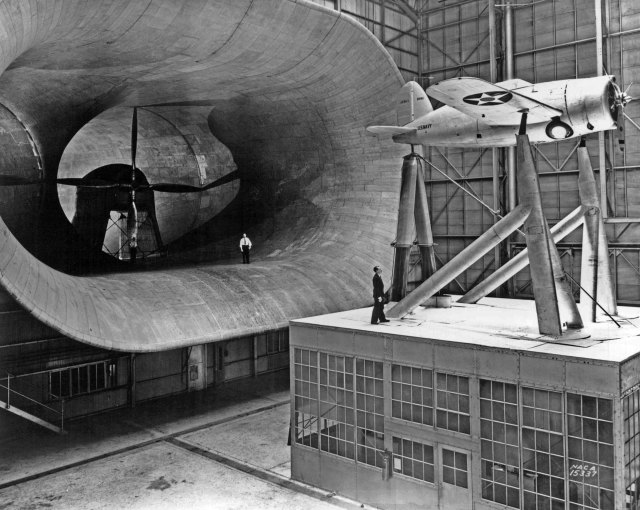

HISTORIC FACILITIES

Historic Facilities

Get to Know Past Facilities at Langley

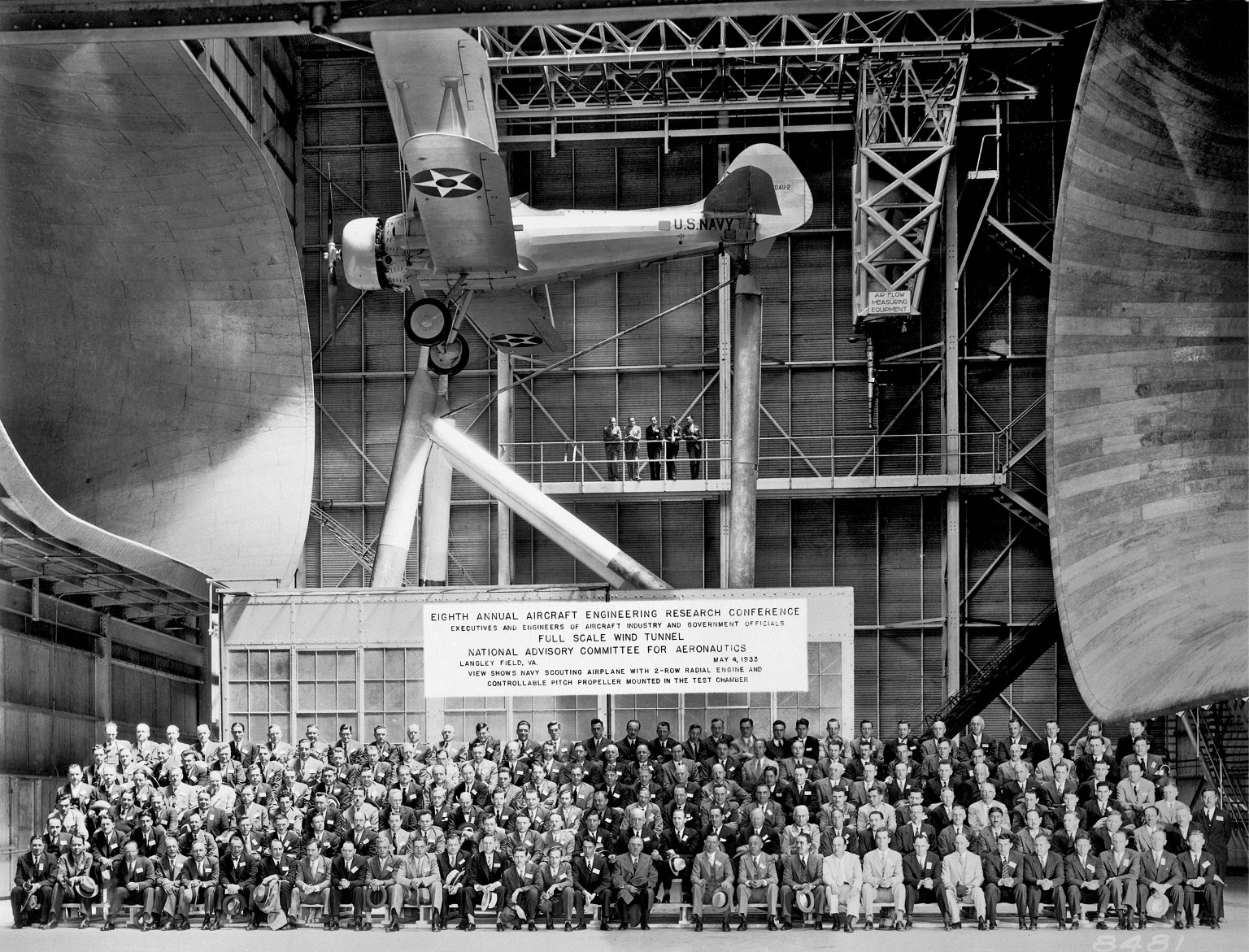

For over a century, NASA Langley Research Center has been home to groundbreaking facilities where history was made. As new facilities are built on center to help usher in the next century of innovation, over the years, these historic facilities have been demolished. Learn about some of these past Langley facilities and the scientific achievements they lead to.

Read More

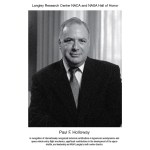

The Hall of Honor

Celebrating the Achievements of NASA Personnel

The Hall of Honor was established by members of the Langley Alumni Association and NASA Langley as a way to pay tribute to individuals who built exemplary careers at Langley, persevered against the status quo when required, and achieved revolutionary scientific understanding and technological progress on the frontiers of the aerospace sciences.

Read More

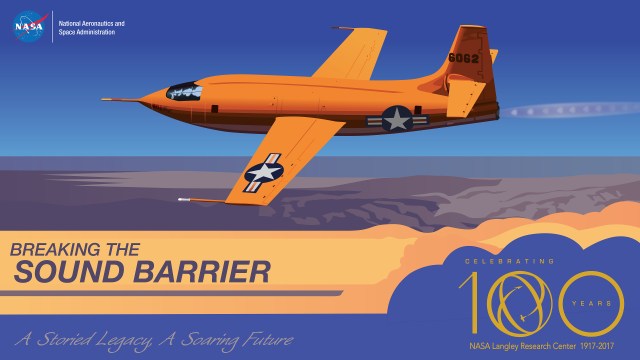

Celebrating Our Centennial

A Storied Legacy, A Soaring Future

The NASA you know today was established in 1958. But its historical roots reach back to 1915–just 12 years after the Wright Brothers’ flight and two years before America’s entry into World War I–when the U.S. Congress created the National Advisory Committee for Aeronautics, or NACA.

In 2017, NASA Langley Research Center celebrated 100 years of excellence in aerospace achievements, scientific discoveries and technological breakthroughs. Learn more about our rich history and what to look forward to in our second century.

Langley Research Center Directors

Langley's Centennial: A Storied Legacy, A Soaring Future

Katherine Johnson: A NASA Trailblazer

One of NASA's famous "human computers," Katherine G. Johnson stands among NASA’s most inspirational figures.

Learn More about Katherine Johnson: A NASA Trailblazer